i4 | INVERTER RESISTANCE SPOT WELDER

The i4 Inverter Resistance Spot Welder is designed to handle difficult to weld materials such as boron steels and Advanced High Strength Steels (AHSS). These new metals are rapidly becoming the material of choice among car manufacturers. The i4 includes an OEM programmable feature with detailed repair illustrations and customized weld programs.

Double-Acting Spot Gun

New innovative Spot Gun from Pro Spot features a double-acting cylinder, wide-spreading electrodes, and self-aligning electrodes.

Extension Arms

The Pro Spot i4 comes with a variety of extension arms to accommodate any welding job situation.

Single-Sided Welding

10 different Single-Sided welding applications give you the power and versatility to complete any job.

Control Panel

The i4 features a large 4”x 6” monitor capable of displaying instructions and OEM repair procedures.

i4 Software

The i4 Software is stored on an upgradeable flash card. We consistently release the latest and newest repair procedures and features to keep you up to date.

i4 Combi: Built-in MIG Welder

The i4 features an easy upgrade to include a PR-155 MIG welder. It can be installed later as an upgrade package or ordered with a MIG welder built-in from the factory.

i4 Overhead Installation

The Pro Spot i4 is available in an overhead ceiling-mounted version. The ceiling-mounted version hangs from the ceiling at 20' bracket spacing giving you extra floor space and accessibility.

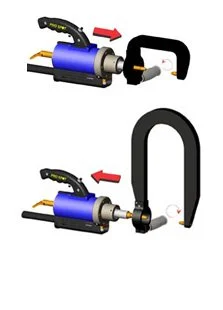

PS-500 DOUBLE-ACTING SPOT GUN

Push one button to open electrodes wide, then push the other button to close electrodes and weld. Pro Spot's PS-500 Spot Gun System features electrode pressure over 600 Lb. with all extension arm sizes.

EXTENSION ARMS

Changing the arms on our weld guns is quick and easy.

PS-503 (optional)

600mm U-Arm

PS-305

508mm U-Arm

PS-306 (optional)

C-Arm Deep (280mm)

PS-403 (optional)

X-Adapter

PS-302

C-Arm

PS-52-5/8

Wheelhouse Arm

The i4 comes standard with several different types of weld arm extensions (508mm U-Arm, C-Arm, Wheelhouse Arm) and others are available upon request, so that you can tackle any welding problem with as much ease and accuracy as possible.

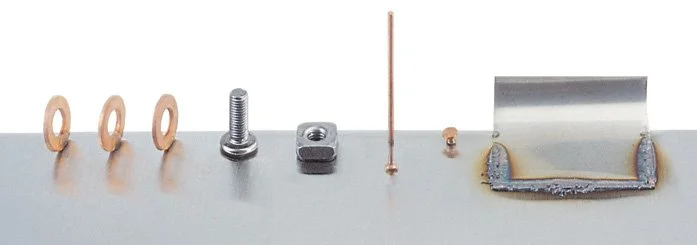

SINGLE-SIDED WELDING

The i4 is capable of handling a variety of single-sided welding needs, including:

washer, nut & bolt, nail, rivet and stitch.

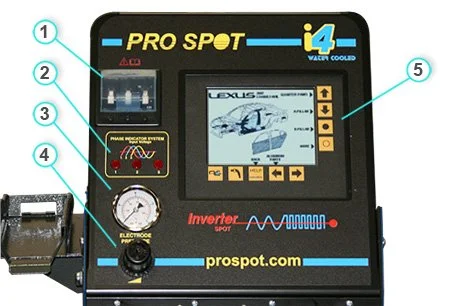

FRONT PANEL

The i4 features a clean, ergonomic interface layout with the power switch and electrode pressure knobs all set in a convenient and straight forward manner. It also has a large 4x6" monitor capable of displaying images and OEM repair procedures.

Power Switch

3 Phase Power Indication Lights

Electrode Pressure Gauge

Electrode Pressure Control Knob

Display Screen

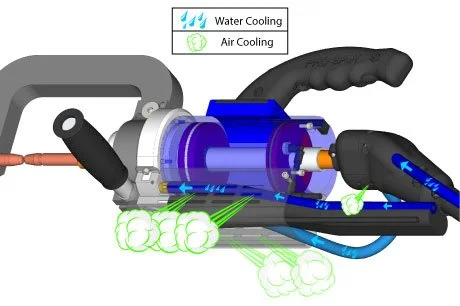

COOLING SYSTEM

Cooling system for i4:

The i4 is both water cooled and air cooled. The air cooling starts when the temp reach 42c and shuts off automatically at 37c. Welding can remain while air cooling is on.

The water cooling is loop based system that cools the transformer weld cables and spot gun. While the water cooling is running the welder can operate as normal.

The reason for the two cooling system is that Pro Spot found it being most efficient and will extend the duty cycle of the welder.

i4 SOFTWARE

The i4's software is easily upgraded with a removable Flash Card as new data and information become available. The latest i4 software features over 3,000 GM OEM repair screens including Dodge, Toyota, Lexus, Volvo, and more.

The i4 data log feature is an easy way to manage weld history, quality of welds and power applied to each weld. Detailed information is stored in an excel file stored on a removable USB flash drive.

Weld-Bonding program for your advanced steel applications. Current is controlled via stored parameters. Amperage Feedback Display: Shows the exact amount of current being used by the welder for each weld.

Access over 3,000 OEM Repair Screens (including: GM, Toyota, Lexus, Volvo, Dodge and More!) as well as general welder help and maintenance on-board.

MIG COMBINATION

The i4 package can include a MIG welder as an option. It can also be installed later as an upgrade. This feature allows the convenience of STRSW and MIG welding in one unit.

MIG FEATURES

220V 1-phase ready to use

Binzel connector: quick-connect all-in-one adapter

Ideal for collision repair welding

OVERHEAD INSTALLATION

The i4 has an overhead installation option. With the overhead option, the welder hangs from a track system that can cover up to 14 bays.

OVERHEAD FEATURES

All the features of a portable i4 welder. ( Optional MIG welder included. )

Convenient overhead mounting system.

No cables, air hoses or equipment on the floor.

Always connected, ready to weld.

Stores out of the way when not in use.

Moves easily around the shop.

Saves valuable shop floor space.

TECHNICAL SPECIFICATIONS

Input Voltage:

3 phase

208 - 240v 50/60Hz

400 - 420v 50/60Hz

460 - 480v 50/60Hz

Welding Amperage:

12500A max (3-phase)

Cable Length:

8' (2.5m) standard

Electrode Pressure:

7 bars (90 PSI)-280 DaN (616 Lb)

Cooling System:

Air (2 fans), Compressed air

(weld gun and weld cables)

Water cooling

(inverter, transformer, welding gun)

Microprocessor:

i4 Upgradable Software Platform

Protection:

IP 21

Patents (3):

no. 5,239,155

no. 6,706,990

no. 6,539,770

Shipping Weight

373lb (169kg)

FEATURES

Inverter Technology, 2000Hz.

Liquid Cooled

Fully Upgradeable Software Stored On Removable Flash Card

Designed For New Advanced Steels: AHSS, HSS, T.R.I.P, BORON

Current Sensing Technology

OEM Repair Procedures On-Board

Multiple languages, Change On-The-Fly

4 Cable System

3-Phase Input

Double-Acting Spot Gun

Two Sided Spot Welding

Single-Sided Welding

X-Gun Adaptive (optional)

Upgradable To Overhead Installation (optional)

Built-In MIG Welder Available (optional)