NEW PLASMA TABLES AVAILABLE

Weldrite Repair does Retro's, Integrations, and Preventative maintenance for all plasma tables. We specialize in transforming old plasma tables to run like new. We also offer our own software package for CAD/CAM/CNC.

WE ARE NOW SELLING PLASMA TABLES AS OUR MADE-IN-USA LINE TO SUIT YOUR EVERY NEED. FROM THE HOME GARAGE TO HEAVY INDUSTRIAL, WE HAVE A TABLE AND CUTTING SOLUTION FOR YOU!

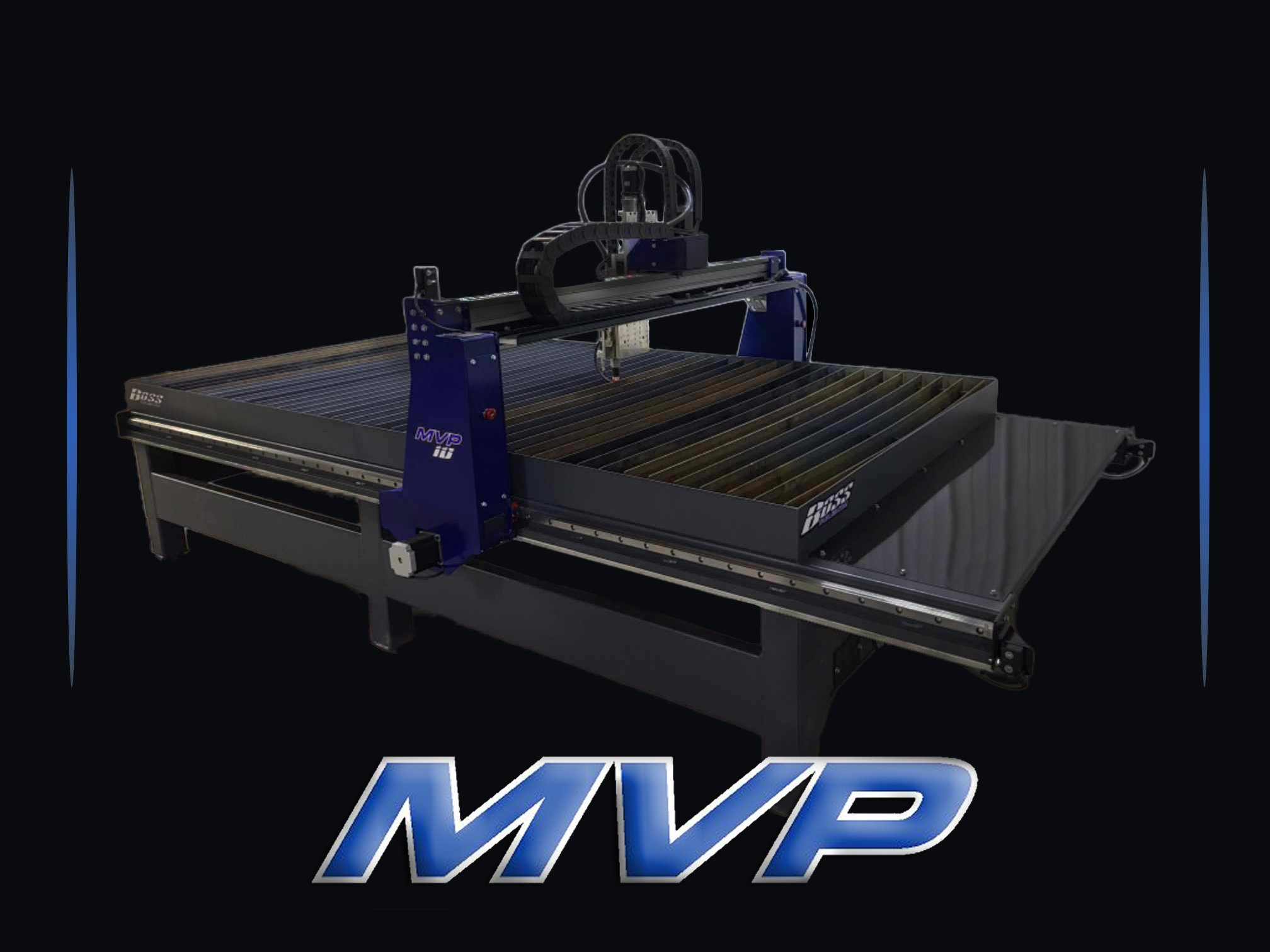

MVP

Ease Of Use- Your Weldrite Table will quickly and easily cut out any number of parts. The Linux-based Computer system uses the HALO cutting program along with Sheetcam for nesting operations. CAD designing is done with Inkscape and QCad. It also can be coupled with any existing CAD program of your choice Table will quickly and easily cut out any number of parts. The Linux-based Computer system uses the HALO cutting program along with Sheetcam for nesting operations. CAD designing is done with Inkscape and QCad. It also can be coupled with any existing CAD program of your choice.

HD ELITE: Heavy Industrial

Meet the HD Elite table, your ultimate partner for 24/7 heavy industrial use. Created for supporting multiple torches, Oxy, and drill. This table is the ideal choice for heavy industrial large-scale companies.

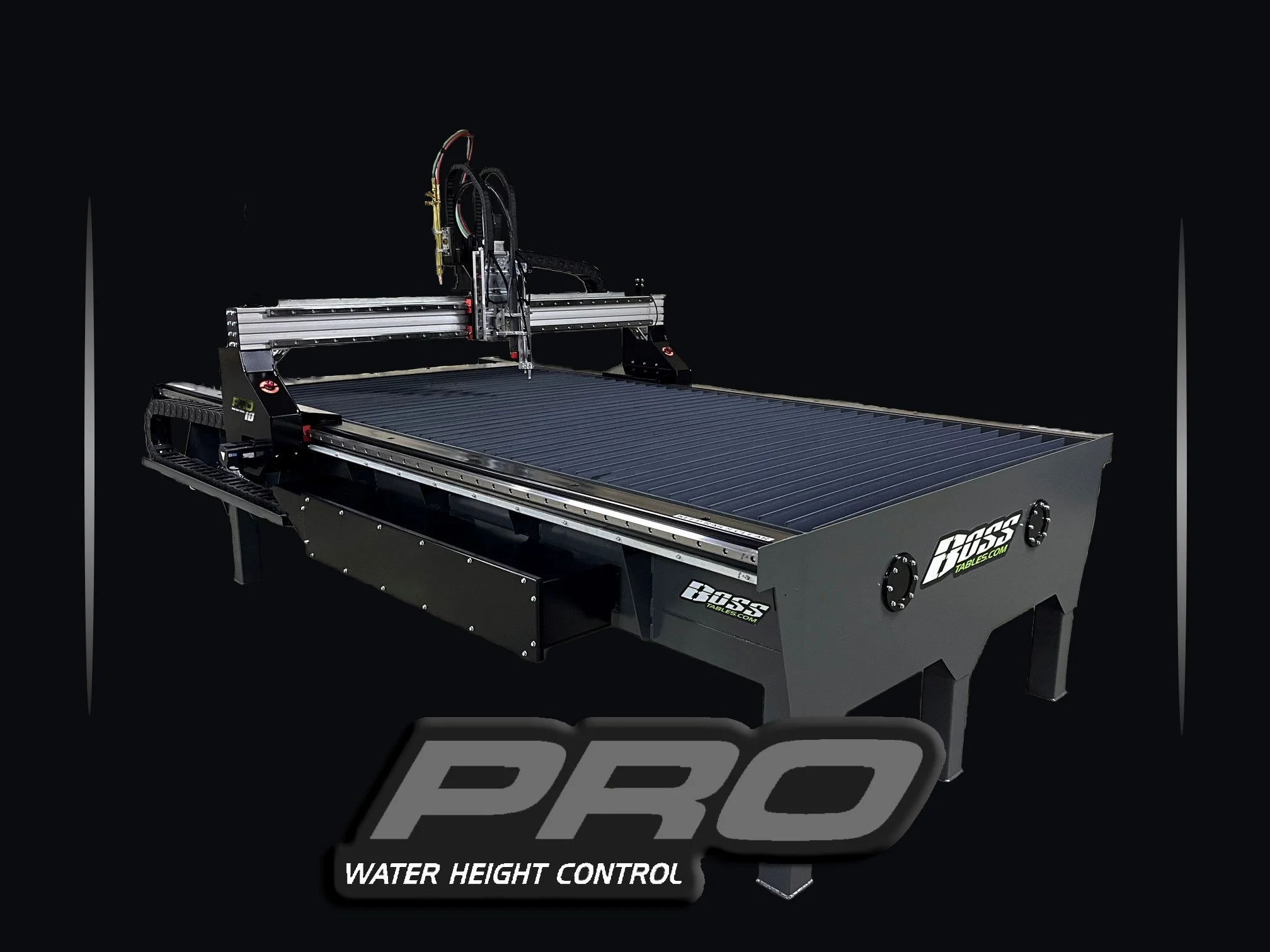

PRO

While it shares the same foundational build quality as the WHC series table, its unparalleled popularity can be attributed to the exceptional software that powers it.

The PRO series tables are Windows-based and operate using the all-in-one FlashCut software, renowned for its user-friendly interface. With FlashCut, even those new to CNC operations can quickly get up to speed and start cutting effortlessly. Paired with high-performance Servo motors and 10:1 gearboxes, the PRO series table transforms into a powerhouse of precision and capability.

Downdraft: Industrial

Enhance your manufacturing efficiency with our Downdraft table, tailored for large to mid-level companies. Compatible with up to 18-inch fans that can be conveniently mounted on either end of the table, prioritize precision cuts, and maintain a clean workspace with this advanced solution.

WHC

Simplicity in Action: The WHC Table efficiently and effortlessly cuts out an array of parts in any desired quantity. Powered by a Linux-based computer system, it uses the HALO cutting program, complemented by SheetCam for nesting operations. This table is equipped with Inkscape and QCad for CAD designing and it can also integrate smoothly with your preferred existing CAD program.

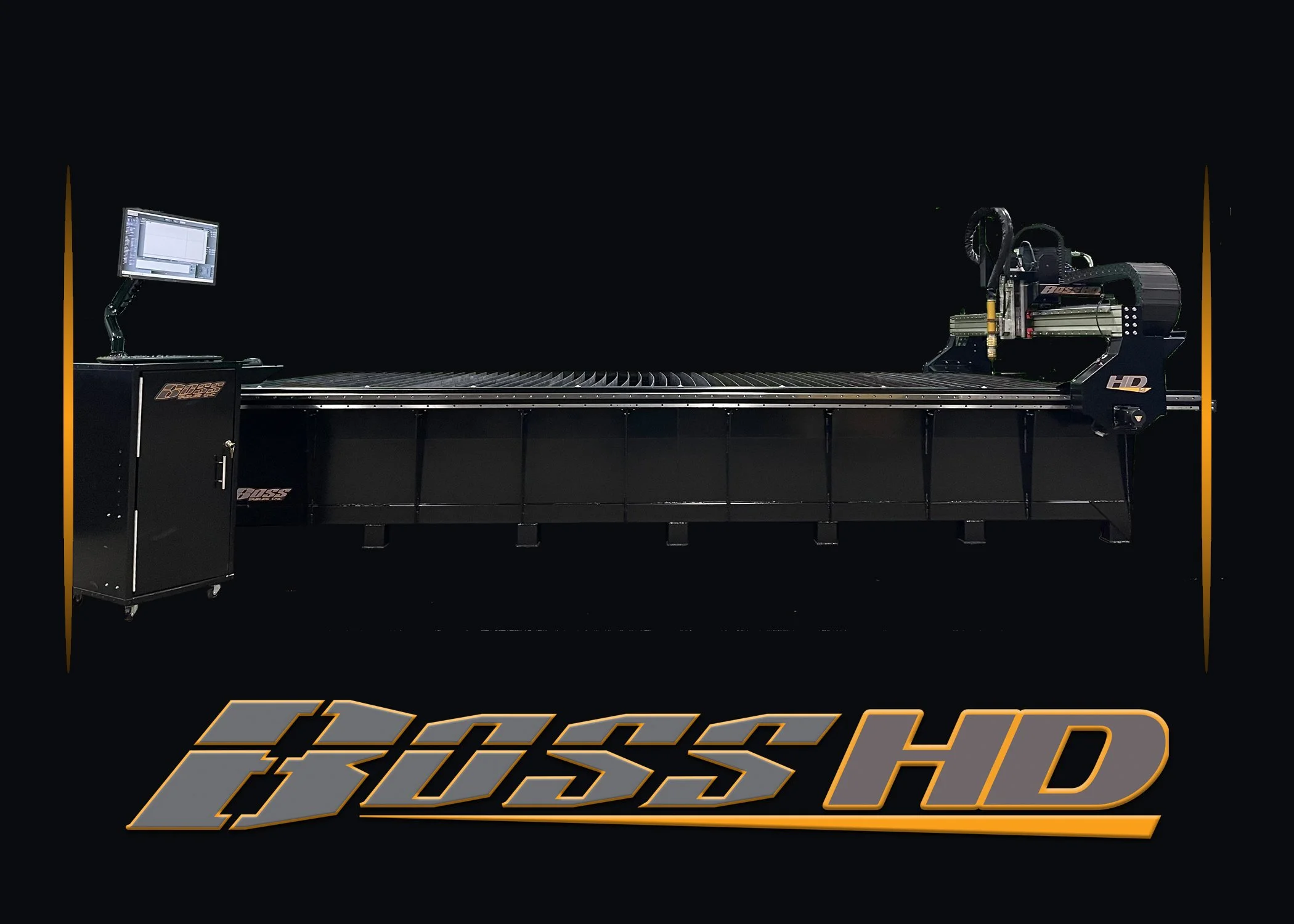

HD: Industrial

Elevate your workspace with a cost-effective powerhouse for large plate processing. This machine was designed for entry and mid-level users wanting to dive into large-scale plate cutting. This table utilizes water height control, making every cut count and setting a new standard for efficiency and accuracy.